±0.01mm Z Repeatability|60% Lower Peel Force|Up to 8000 cps Resin|Dual Color & Material|Auto Temp Control|Photon P1

Check on Kickstarter

*Please refer to Launch Giveaway section for more details

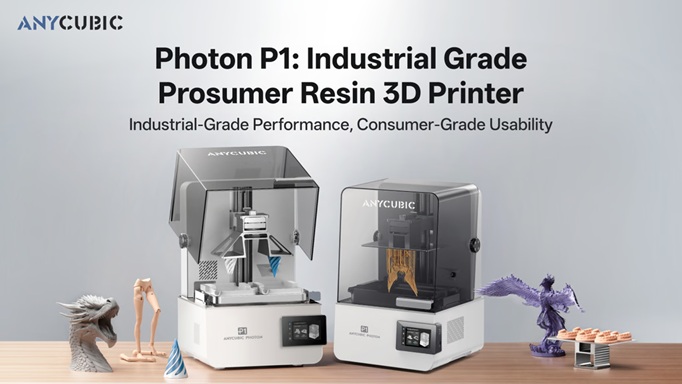

Looking for broader resin compatibility, higher success rates, and finer detail? Photon P1 delivers industrial-grade reliability at a consumer-friendly price, giving you the freedom to use high-viscosity resins and achieve consistent, high-precision prints with ease.

Most desktop printers tap out at 2,000 cps. Photon P1 handles up to 8,000 cps—unlocking high-viscosity engineering resins, dental materials, and elastic composites previously industrial-only. From production dental work to collectible batching, material choice becomes creative freedom rather than technical limitation.

Consistency begins with three systems working in concert. Wave Release Technology cuts peel force 60% for clean layer separation. Industrial-grade ball screw achieves ±0.01mm repeatability across thousands of cycles. LighTurbo 4.0 delivers >92% illumination uniformity at 112 points. Complex geometries and fine details reproduced faithfully. When print 1 succeeds, print 1,000 succeeds identically.

Print two colors or materials in a single job—no separate prints, no assembly delays. With Photon Workshop 4.0, Photon P1 can apply different parameters simultaneously, from dual-hardness dental models to multi-color figurines. The optional Dual-Material Print Kit minimizes expensive resin waste on small prints or handles full 6.5L builds. Creative freedom without compromise.

*Dual-Material Print Kit sold separately.

Industrial resin printers deliver exceptional precision at $1,000+ price tags that lock out most creators. Photon P1 closes the performance gap. It delivers near-industrial capability without industrial overhead. That’s the breakthrough.

At Germany’s Formnext 2025 exhibition, industry professionals, print farm operators, and advanced makers experienced P1’s near-industrial printing capabilities firsthand. The response? Consistent validation of build quality, printing stability, and material versatility. When your reputation depends on output quality, peer validation matters. P1 earned it.

This new video from Scale Model Geek is a must-watch. It offers an early look at our latest Photon Workshop 4.0, along with quick previews of validation models and ultra-fine prints that showcase the P1’s precision.

Greedy 3D highlighted the Photon P1’s outstanding performance. Its 14K screen and LighTurbo 4.0 system deliver highly detailed models. The built-in camera lets you monitor prints in real time, and the supports are easy to remove, making it easy for beginners to get started.

In this video, SpensPainting showcases the Photon P1’s wide resin compatibility and industrial-grade ball screw system. The P1 is easy to operate and delivers high-quality, detailed prints.

Industrial-grade ball screw achieves ±0.01 mm repeatability across 10,000 cycles and Z-axis precision within 0.02 mm. These aren’t launch-day specs—they hold through long-term use. The result: uniform layer thickness, smooth surface transitions, and consistent dimensional accuracy without degradation. Print 1 matches print 1,000.

Precision-Milled Steel Plate for Reliable Performance

Precision-Milled Steel Build Plate (flatness tolerance <80 μm) outperforms aluminum in flatness, wear resistance, and adhesion stability, which is critical for warp-free bases and consistent layer thickness. For high-viscosity industrial resins up to 8,000 cps, the optional Perforated Steel Build Plate lowers downforce, ensuring stable prints with challenging materials.

*Perforated Steel Build Plate sold separately.

Precision Screen Alignment for Flawless Prints

Photon P1’s 14K LCD (16.8 μm X-axis, 24.8 μm Y-axis) captures fine details. The <70 μm installation flatness ensures uniform light projection and consistent layer thickness, directly impacting first-layer success. True precision comes from systems integration: flat LCD, optimized optics, industrial-grade motion. Components working in concert, not specs in isolation.

This system adds a high-transparency wave-textured layer above the screen, which works with the NFEP film to ensure uniform light transmission for precise curing. Wave Release Technology, which forms controlled micro-airflow as the build plate lifts. This reduces peel force by up to 60%, allowing each layer to separate smoothly while keeping adhesion stable. The result: stable adhesion, flawless surfaces, quieter operation.

More Precise, More Vertical Light

Sharper light, sharper prints. Built with an aspherical Fresnel lens, LighTurbo 4.0 achieves collimation accuracy of <2°, ensuring every beam travels straight and true to cure each layer precisely. The result: sharper layer boundaries, cleaner contours, finer details. No halos. No ghosting. Just flawlessly defined surfaces.

More Uniform Light

Full-screen rolling calibration delivers >92% illumination uniformity across 112 measurement points. Center to edge, brightness remains constant; no overexposure, no underexposure. Every inch of the build platform receives balanced exposure. Multiple prints maintain uniform size, precision, and surface consistency. Each layer aligns seamlessly, forming a flawless whole.

The Final Result

Sharper light. Smoother prints. <2° collimation and >92% uniformity translate to visible quality: crisper edges, cleaner layer transitions, finer detail resolution. Every layer cures with precision, eliminating soft boundaries, surface inconsistencies, and compromised features. The result: prints that look remarkably clean and precise. LighTurbo 4.0 perfects what light creates.

Compatible with industrial resins up to 8,000 cps, from BJD figurines and dental models to high-temperature engineering materials. Wave Release Technology and Intelligent Dynamic Lift 3.0 System adapt in real-time, adjusting height and speed based on resin viscosity. Strong adhesion. Smooth separation. Consistent curing across the entire material spectrum. Ultra-viscous industrial resins perform flawlessly on a desktop device.

Dual-component printing typically requires machines costing over $1,000. Photon P1 delivers it at a fraction of that cost, handling elastic materials and up to 8,000 cps resins with steady control. The Perforated Steel Build Plate works to reduce downforce, improving success rates. Strong, precise, consistent results, even through long-term production use.

Two Colors. One Resin Type. Zero Interruptions

Pour two colors of the same resin type into separate tanks, set parameters in the slicer, and print. Both colors process in a single run without mid-print material swaps. The time and setup costs of sequential printing? Eliminated. Multi-color results without multi-stage workflows.

*Dual-Material Print Kit sold separately.

Dual-Material Printing At Once

Assign different resin types to each tank directly in the slicer. Each material follows independent exposure parameters during the same print job. Both materials maintain their precision simultaneously. With its partitioned layout, the system also helps minimize material consumption when working with premium resins. One model. Multiple material properties. Complete functionality in a single build.

*Dual-Material Print Kit sold separately.

Dual-Color & Dual-Material Use Cases

Dental professionals: print gingiva models with rigid bases and flexible soft tissue in one build.

Figurine creators: produce multi-color character designs without assembly or painting prep. Prototype engineers: combine rigid structural components with flexible gaskets or hinges.

Real applications. Real efficiency gains. Real cost savings by eliminating post-processing.

High-viscosity resins demand precise temperature control. The intelligent 1000ml Temperature-Controlled Resin Vat automatically adapts to different resin types, maintaining optimal flow (up to 40°C) for consistent curing.

No manual temperature adjustments. No guesswork. Just higher print success rates, especially critical when working with premium industrial-grade materials where every failed print costs significantly.

With Intelligent Leveling System 3.0, each machine is factory-calibrated for perfect flatness out of the box. Before each print, the system adds smart-assisted checks to help maintain precise leveling throughout use. You press print. P1 handles the technical foundation. High success rates from print one.

Smart Dynamic Balance 3.0

Intelligent Dynamic Balance 3.0 System continuously monitors peel force during layer separation, automatically adjusting height and speed in real-time. Large solid models separate without cracking. Detailed designs preserve fine features. And with high viscosity to flexible resins, the system adapts automatically. No manual tuning. Smooth lifting across all printing scenarios, even at high speeds. Reliability holds regardless of complexity.

Dynamic Light-Off Compensation 3.0

Calculates resin flow in real-time, automatically adjusting light-off time per layer. High-precision models achieve smoother surface transitions. High-transparent resins cure uniformly without localized over-exposure. Dynamic optimization across all scenarios, extending LED lifespan while ensuring consistent light performance through thousands of prints.

Photon P1’s AI’s built-in camera and AI monitoring continuously track platform placement, model stability. Proactive alerts flag potential issues before they become print failures, reducing material waste and manual intervention. Real-time monitoring and time-lapse recording support long or remote print jobs. Press print. Walk away. P1 watches every layer. AI recognition becomes available once the print reaches a certain height.

Tool-free quick-release mechanism for both build plates and resin tanks. Lift the release lever, remove the plate meaning model removal takes seconds. Swap resin tanks without draining or tools, enabling rapid material changes between print jobs. Streamlined workflow from print completion to next-job setup. Less downtime. More productivity. Designed for professionals running multiple projects daily.

External direct-exhaust design actively pulls fumes through dedicated ventilation rather than relying on passive carbon filters. Air Pure 2.0 continuously removes resin odors during printing, maintaining workspace air quality throughout extended print sessions. Position P1 in shared office or home environments without dedicating separate ventilation rooms. Active filtration outperforms traditional filter-based systems so you print comfortably wherever you work.

*Air Pure 2.0 sold separately.

Hundreds of thousands of free models from global creators. Incentivized sharing programs turn your designs into value. Community forums connect you with prosumers worldwide. AC Wiki provides clear troubleshooting guidance for every error code.

Print from a vast library. Learn from collective experience. Share your innovations.

To celebrate our Kickstarter launch, we’re giving 2 lucky backers the chance to receive a full $499 refund — the price of a single unit. So jump in early, and you might get your P1 completely free. Good luck, and thank you for being part of our launch! 🚀

- Back any rewards within the first 48 hours after launch — no extra steps needed!

- We’ll announce the two winners within 2 weeks of the campaign launch.

- Winners will receive a Kickstarter message from us with the next steps.

- After the campaign ends, we will verify the orders and issue the refund within 14 days.

The image below shows all the items included with the standalone unit, giving you everything you need to start your incredible 3D printing journey.